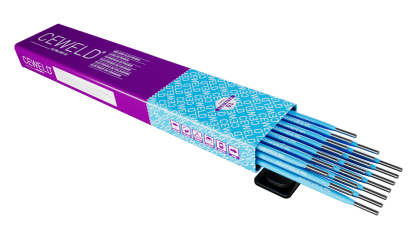

Underwater stick (wet) welding electrode "AquaForce"

It takes a long time to developpe a new electrode for wet welding but we did. 7 years, more than 200 formulations and testing till we run out of oxygen made it possible to make the best electrode for Under water wet welding that is now ready to enter the market.

AquaForce MG, the #1 electrode for under water welding professionals:

- - No inclusions and No porosity

- - Easy operation, first time right

- - Self lifting slag

- - No intermediate cleaning or grinding required between the layers

- - Double coated for safer operation

- - No moisture absorbtion due to double coating

- - Yield strength exceeding 420 MPa

- - Impact strength > 36 Joule at O°C

Image

brochure aquaforce2.24 MB