CE marking gives you the warranty that the goods are delivered within a traceability and quality system that is witnessed by a notified body and confirms to the latest European standards (EN 13479). The unique CPD / CPR number enables the notified bodies to trace the final source of the product to make sure that the whole supply chain is controlled and full fills the latest EN rules.

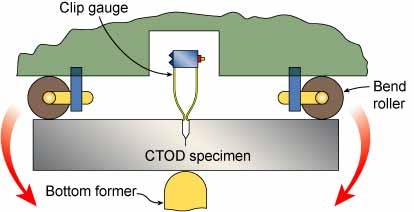

CTOD test for weld-metal (filler metal)

Due to the manufacturing process and two times anealing during the drawing process at 580ºC the hydrogen content in our seamless fluxcored wires are the lowest on the market today (between 2 and 3 ml/100gr weld metal).

The demands for welding consumables are getting higher and higher day by day due to the industry that builds bigger and more demanding constructions. Risk is getting bigger and welding procedures gets more restrictions and better traceability is required. There are many ways to make prior tests for welding joints in order to find the weakest spots and also lots of standards that have to be followed.